In micro-fabrication, etching is used to chemically remove layers from the surface of a wafer during manufacturing. The cleanrooms at IMS carry a variety of tools which can be used for a wide variety of etching processes including oxides, substrates and metal etching. The capabilities of the IMS etching tools are divided into five categories: HF Vapor Etching, ICP Etching Equipment, Plasma Cleaning, RIE equipment.

DRIE/BOSCH processing

KLA SPTS Rapier ICP

The Georgia Tech SPTS Rapier Si DRIE system is a leader in silicon etching, offering both Bosch switched processing and non-switched etching for tapered profiles, wafer thinning, and via reveal. Its patented dual plasma source design features independently controlled primary and secondary plasma zones with dual gas inlets, ensuring a highly concentrated and uniform radical distribution. This design results in high etch rates, excellent uniformity, and precise control over deep feature tilting across the wafer. With customizable recipes controlling gas flows (SF6, C4F8, O2, Ar), platen temperature (-20°C to 40°C), and high bias and ICP power settings, the Rapier system delivers unparalleled precision for a wide range of applications, including MEMS, semiconductor fabrication, microfluidics, TSVs, photonics, and advanced packaging. Its exceptional process capability and cost-effectiveness make it essential for cutting-edge research and development.

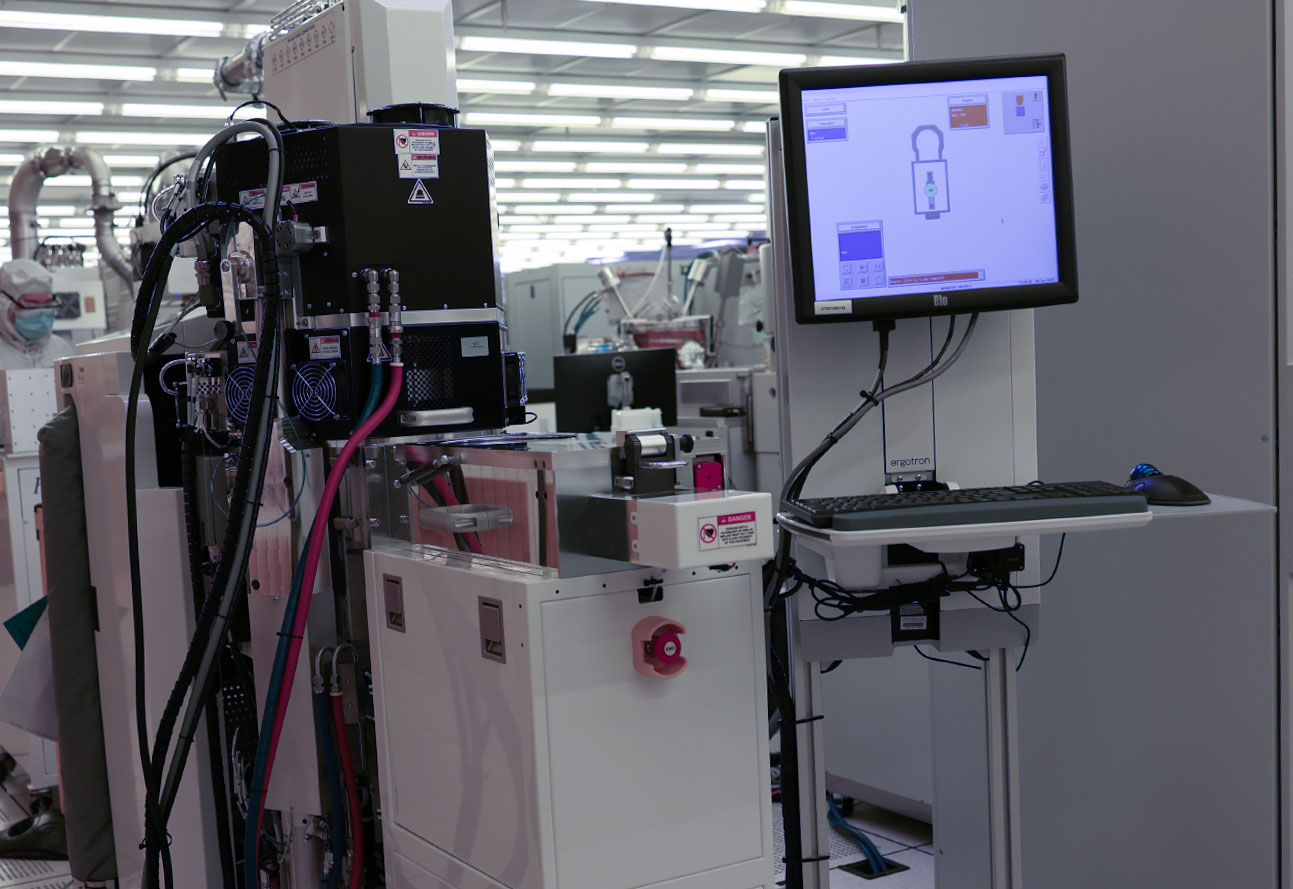

STS Pegasus ICP

The Georgia Tech STS Pegasus ICP is a high-performance deep reactive ion etching (DRIE) tool designed for precise silicon etching using the Bosch process. It delivers over 20 microns/min etch rates, with customizable recipes controlling chamber pressure, gas flows (SF6, C4F8, O2, Ar), platen temperature (-20°C to 40°C), and power settings. The tool is optimized for silicon, photoresist, and SiO2 etching, with excellent sidewall roughness and profile control. Capable of etching through 6-inch wafers, it offers high selectivity, making it ideal for applications such as MEMS, semiconductor devices, and photonic structures, with precise control over trench depths and widths.

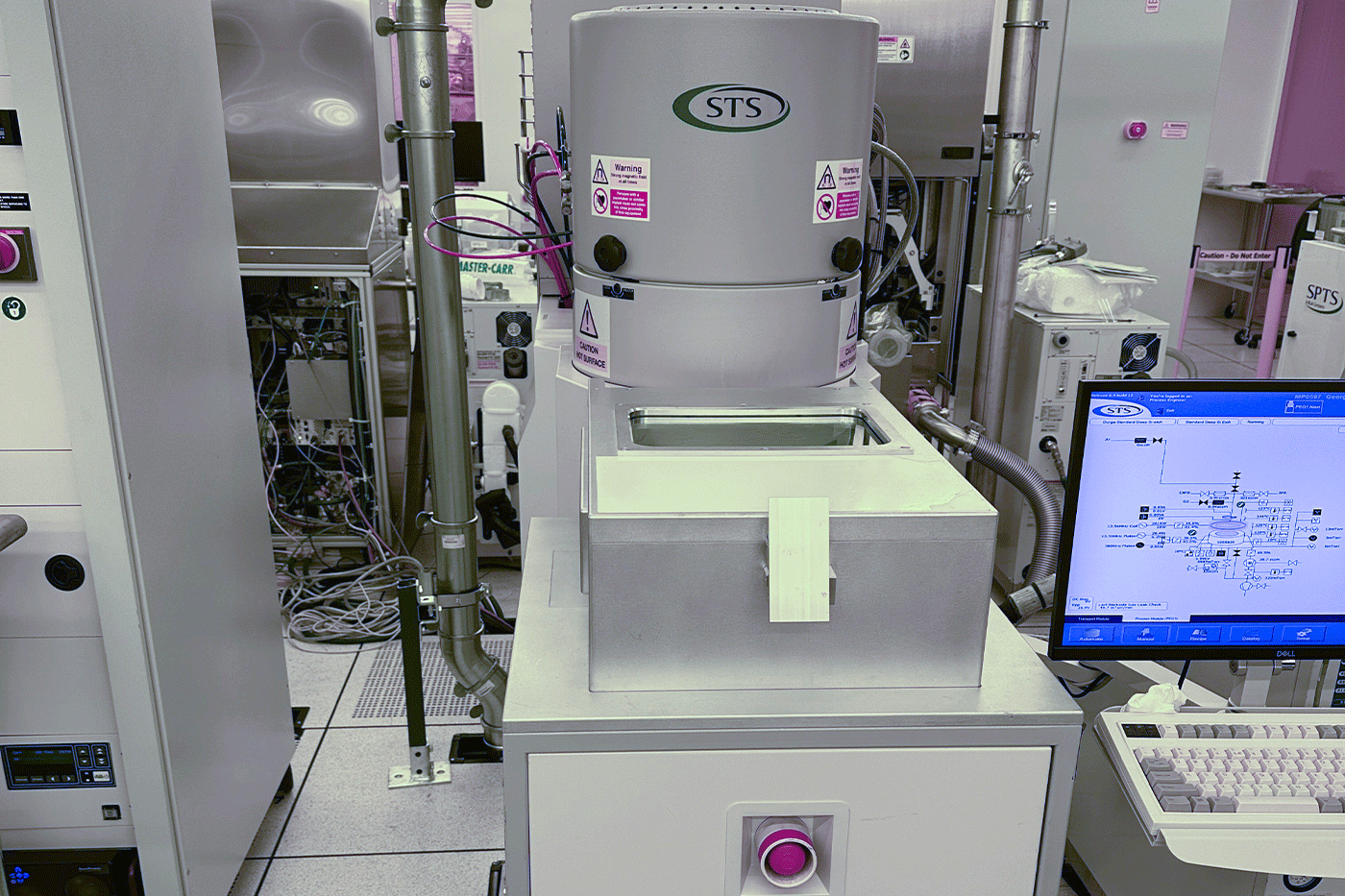

STS Multiplex ASE ICP

The Georgia Tech STS Multiplex ASE ICP is a CMOS-compatible tool designed specifically for integrated MEMS-CMOS processes, focused on high aspect-ratio trench etching in silicon and SOI wafers. This system is ideal for deep silicon trench etching using the Bosch process and for etching high aspect-ratio trenches on 4" SOI wafers. It provides precise control for etching deep, narrow trenches with high selectivity and excellent aspect ratios, making it suitable for advanced MEMS and semiconductor research and development. The tool supports etching using fluorine-based gases such as C4F8, SF6, Ar and O2, ensuring excellent anisotropic etching performance.

ICP Etch

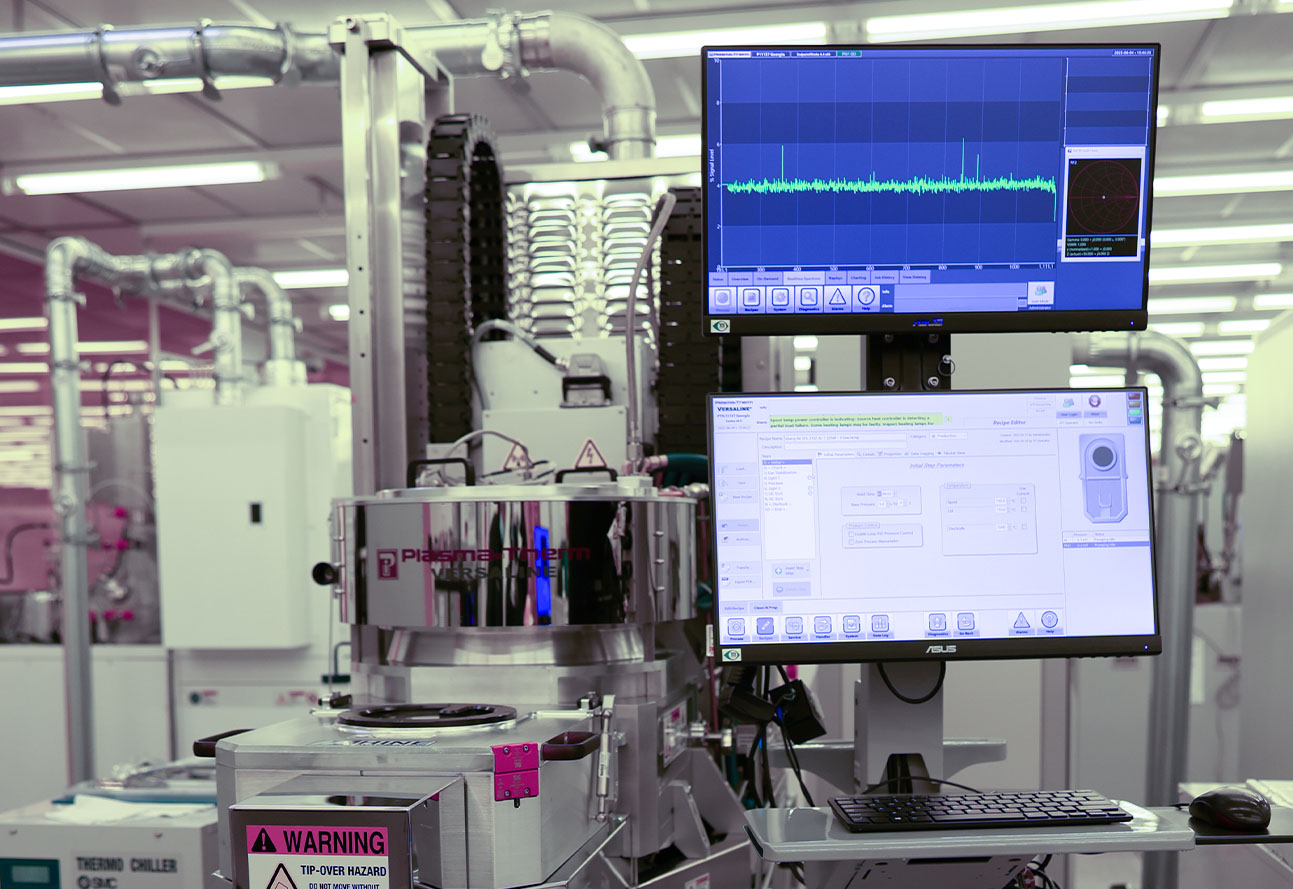

Plasma Therm Versaline ICP (SiC Etching)

The Georgia Tech Plasma Therm Versaline ICP (SiC etching) is designed for high aspect ratio etching of Silicon Carbide (SiC) with smooth sidewalls, making it ideal for advanced SiC processing. The tool is configured for 150mm SiC wafers and smaller samples with a carrier wafer. It utilizes processing gases including SF6, O2, and Ar for etching and features an Electrostatic Chuck (ESC) and Ceramic Mechanical Clamp with Helium Backside Cooling (HBC) to ensure stable substrate positioning and cooling. The substrate holder is cooled by a heat exchanger with temperatures ranging from -20°C to 120°C. Nickel and oxide masks are compatible, ensuring high-quality trench etching in line with industry standards. Applications for this tool include power electronics, high-performance semiconductors, RF devices, and optoelectronics, where SiC is widely used for its superior thermal conductivity, high breakdown voltage, and radiation resistance.

Plasma Therm Versaline ICP (Dielectric Etching)

The Georgia Tech Plasma Therm Versaline ICP (Dielectric Etching) system is designed for precise dielectric etching, particularly for materials like SiO2 and SiNx, delivering smooth, vertical sidewalls. Configured for 100mm wafer sizes and small samples with a carrier wafer, it is ideal for a wide range of specialty semiconductor applications. The system uses processing gases such as CF4, CHF3, SF6, O2, and Ar to achieve high-precision etching. Substrate cooling is managed by a ceramic mechanical clamp with Helium Backside Cooling, and the wafer chuck temperature is controlled by a heat exchanger, ranging from 10°C to 60°C. Known for its versatility, the Versaline platform is a workhorse for both R&D and high-volume production, offering enhanced process control with end point detection. Its modular design allows easy upgrades, making it a scalable solution for a variety of etch and deposition processes in the semiconductor industry.

Plasma Therm Dual ICP SLR Mn F

The Plasma Therm Dual ICP SLR Mn F system at Georgia Tech is a high-density inductively coupled plasma (ICP) etcher with dual chambers, providing flexibility for various etching processes. The right chamber is configured for 6-inch wafer etching, specializing in deep anisotropic silicon etching (using the BOSCH process), poly-silicon, and through-wafer etching. The left chamber is designed for 4-inch wafer etching and III/V etching, including materials like SiO2, Si3N4, Al, and III/V semiconductors such as InP and InGaAs. Both chambers support etching of small pieces on a carrier wafer, using fluorine-based gases like SF6, O2, C4F8, CF4, Cl2, and BCl3. The system operates at pressures ranging from 5 to 80 mTorr, with platen temperatures controlled at 20°C, and the chamber temperature at 40°C, making it ideal for advanced semiconductor research and production.

Plasma Therm ICP single chamber SLR-720 M.F

The Georgia Tech Plasma Therm SLR-720 M.F ICP etcher is a versatile tool designed for etching a variety of materials with high precision. This single-chamber inductively coupled plasma (ICP) system is optimized for shallow silicon (Si) and dielectric etching, accommodating 4-inch wafers and small samples on a carrier wafer. The system is configured for III/V semiconductor etching, including materials like SiO2, Si3N4, Al, and III/V semiconductors such as InP and InGaAs. With etching gases like C4F8, CF4, Cl2, and BCl3, it provides high etch rates and excellent process control. Applications include the fabrication of photonic devices, MEMS, semiconductor devices, and advanced packaging. The system is ideal for high-precision etching needed in optical, communications, and microelectromechanical systems (MEMS) applications.

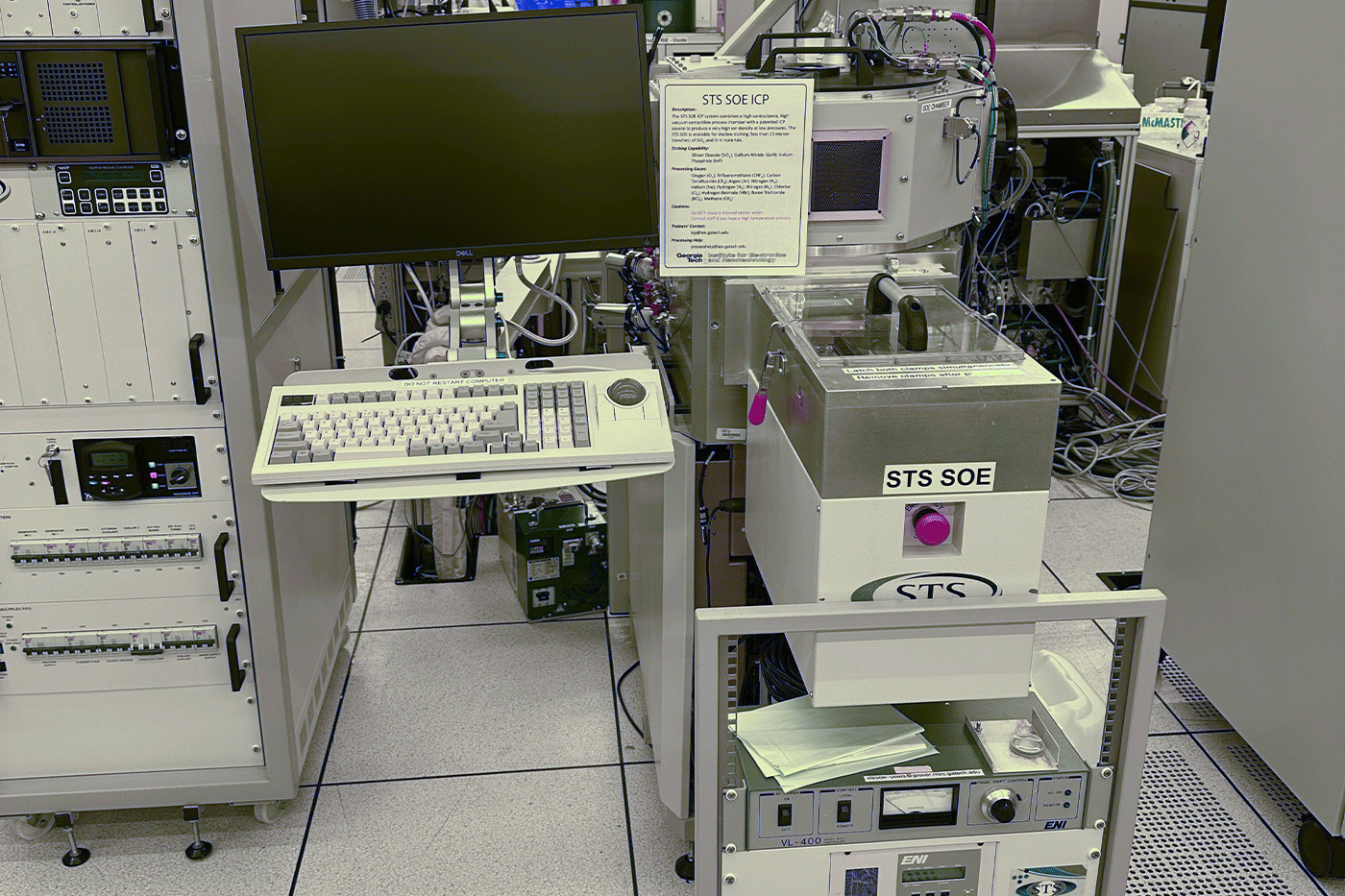

STS SOE ICP

The Georgia Tech STS SOE ICP system is a high-performance ICP etcher designed for shallow etching applications, such as silicon trench etching and III-V material processing. The system features a patented ICP source that delivers high ion density at low pressures, ensuring higher etch rates, better selectivity, and high aspect ratios compared to conventional RIE tools. It operates with chlorine-based etch gases, including Cl2, BCl3, O2, and Ar, minimizing cross-contamination. With a 4-inch wafer capability and a temperature range of -20°C to 180°C for the platen, this system excels in processing Si and III-V materials with precision.

RIE Etch

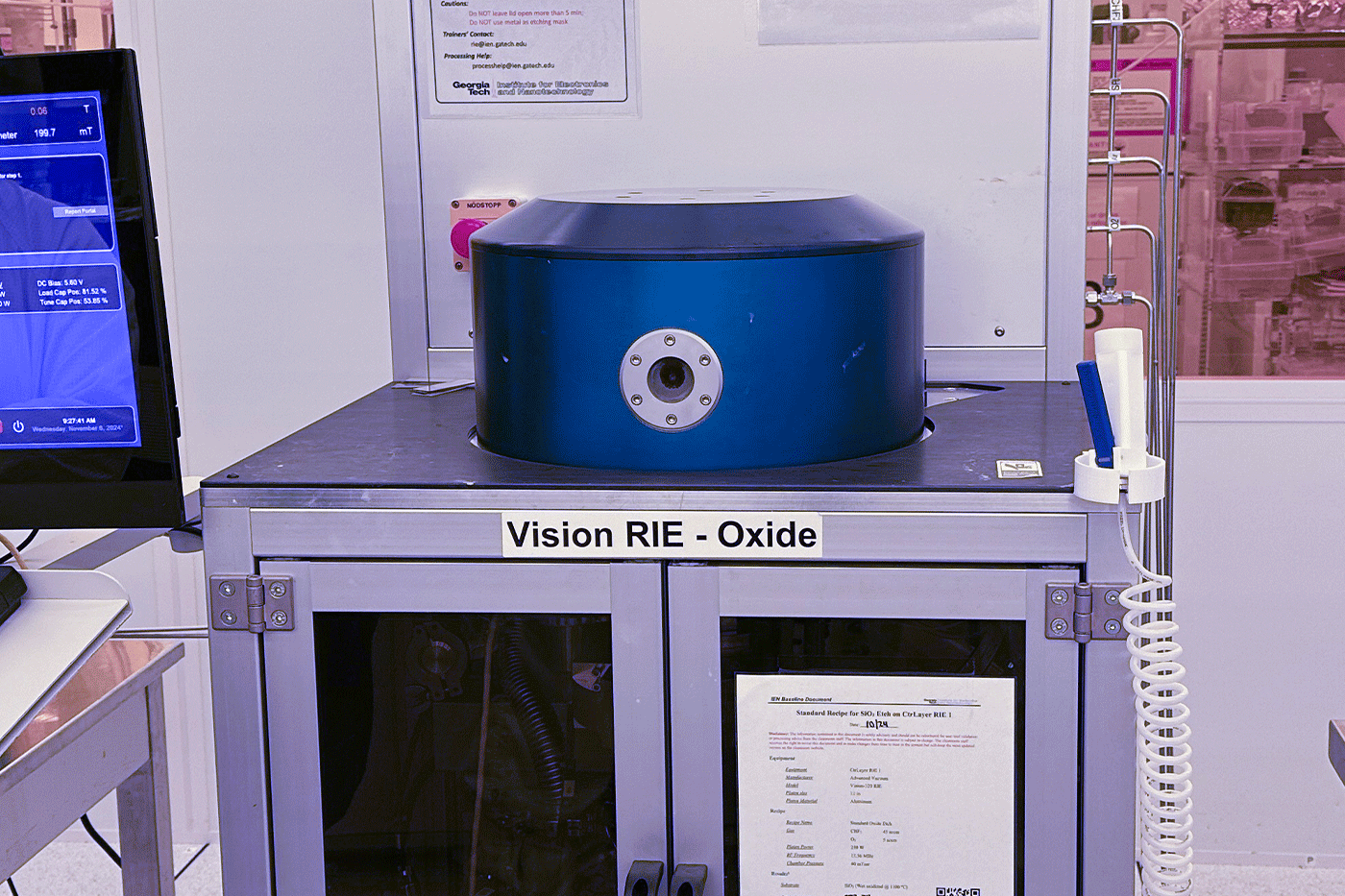

Vision RIE 1

The Georgia Tech Advanced Vacuum Vision 320 RIE, is a versatile and reliable Reactive Ion Etcher (RIE) system designed for etching dielectric materials and shallow silicon. With its updated software developed by IMS, the system offers precise control for etching applications using gases like SF6 and CHF3. The Vision RIE features a permanent graphite plate that helps dissipate heat, preventing temperature buildup during long etching processes. It is capable of processing small pieces and up to 8-inch wafers, making it ideal for etching materials such as SiO2, Si3N4, shallow Si, and shallow SiC. The system supports photoresist masks and operates with a wide range of gases, including Ar, N2, O2, CHF3, and SF6, at pressures from 10 to 800 mTorr. This makes it an excellent choice for high-precision etching in both research and development.

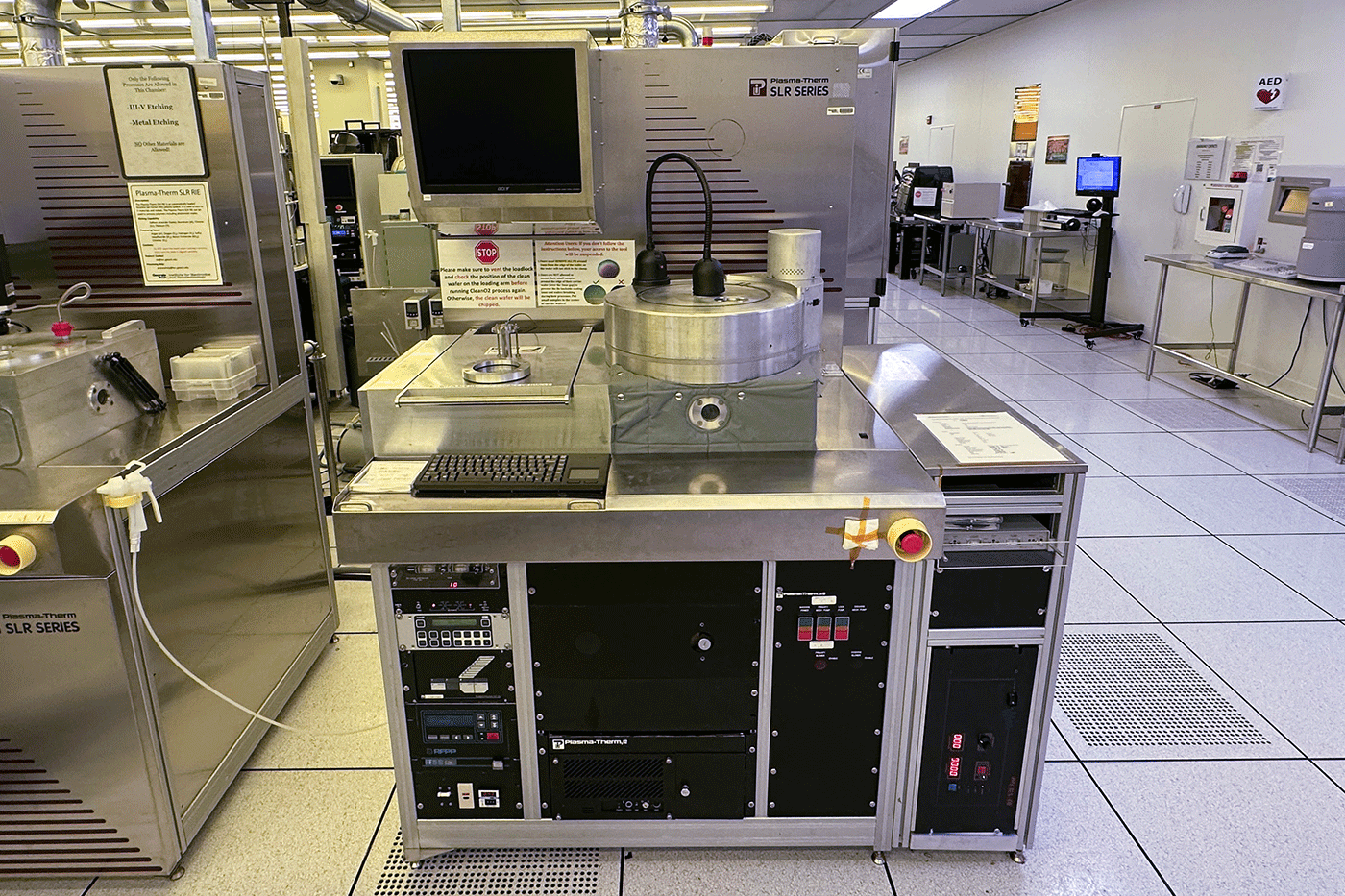

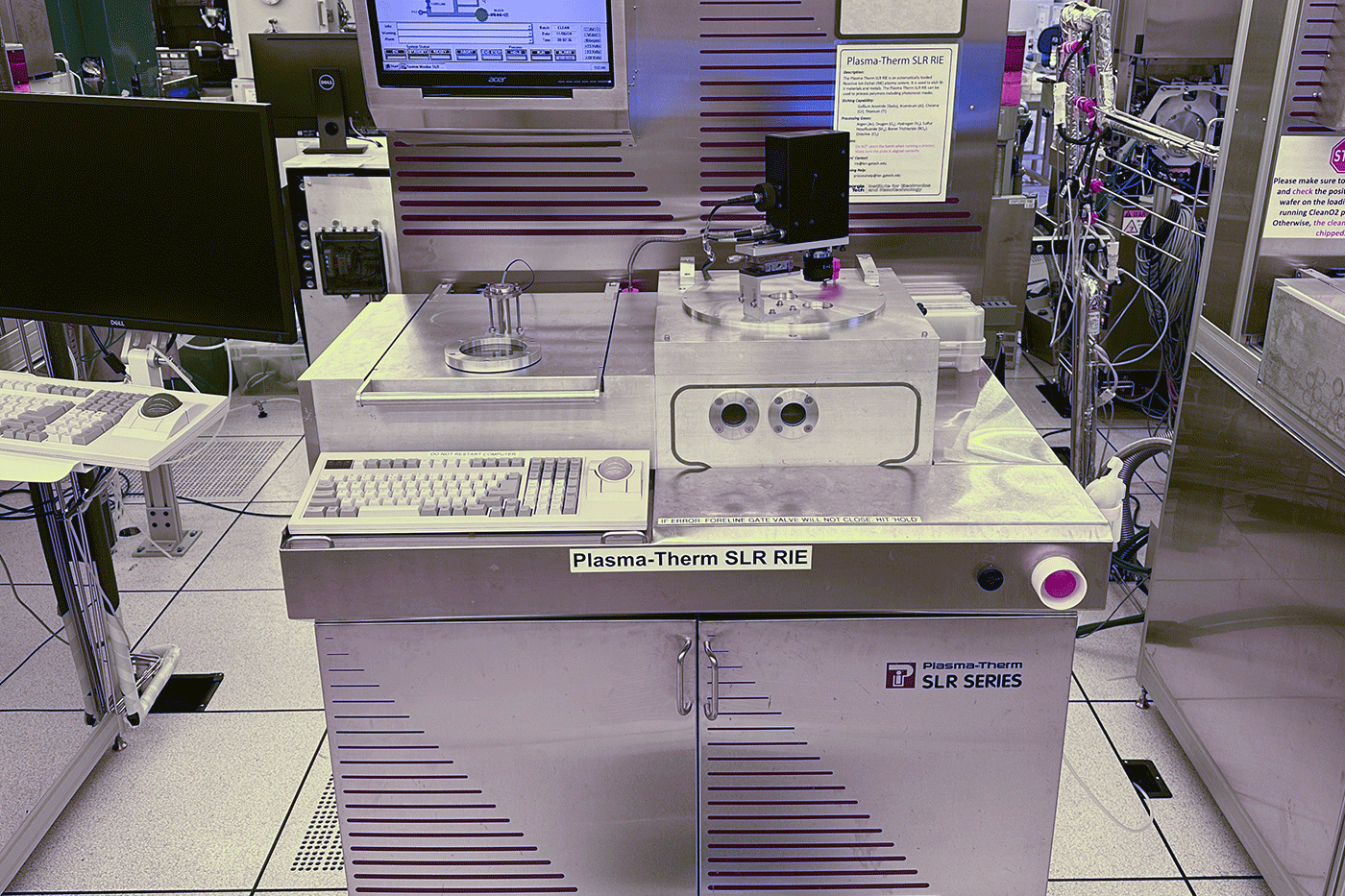

Plasma Therm SLR RIE

The Georgia Tech Plasma-Therm SLR-720 MF RIE is an automated Reactive Ion Etcher (RIE) plasma system equipped with a loadlock system for efficient wafer handling. This system is designed for etching III-V materials and metals like aluminum, including photoresist masks. Operating at 13.56 MHz, the RIE uses reactive gases such as BCl3, Cl2, Ar, and O2 for precise etching. It supports small pieces and substrates up to 8 inches. The loadlock system ensures clean and controlled wafer loading, making the Plasma-Therm SLR-720 MF ideal for high-quality semiconductor processing applications.

Plasma Therm 790 RIE

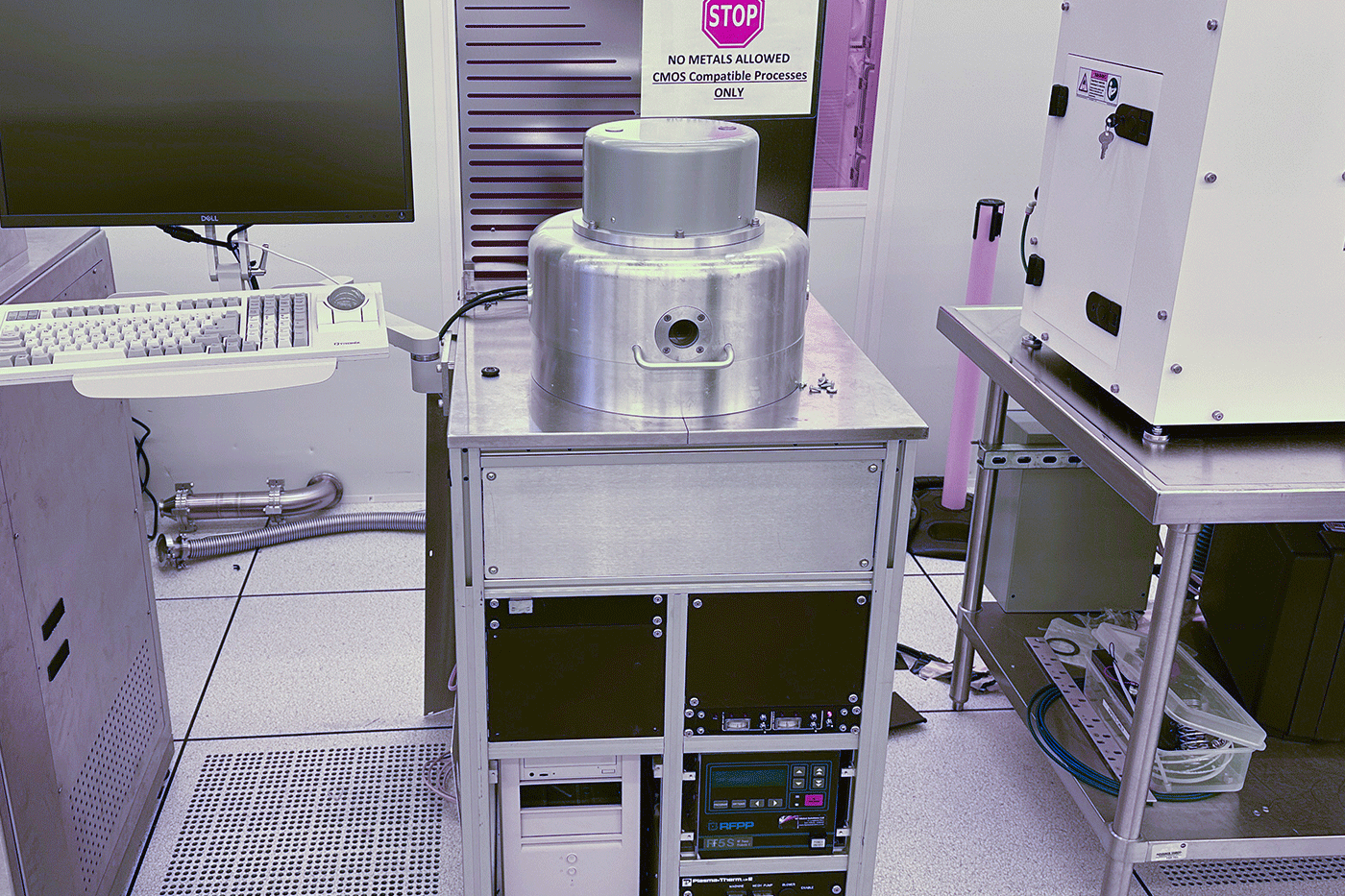

The Georgia Tech Plasma-Therm 790 (790 8V RIE MF) is a stand-alone Reactive Ion Etching system designed for precise etching of materials such as silicon dioxide, silicon nitride, and thin polymers, including descum processes. Equipped with a showerhead gas distribution and a water-cooled RF platen, the system operates with gases like SF6, CHF3, Ar, and O2, each controlled by a mass-flow controller (MFC) to ensure accurate gas delivery. The chamber reaches a base pressure in the 3x10^-5 Torr range, with a working pressure range of 10mTorr to 800mTorr, making it highly flexible for different etching applications. The system is compatible with up to 8-inch wafers and is CMOS process compatible, offering both manual and automatic operation modes through its intuitive control program. Ideal for research and development, this tool ensures high precision and versatility in semiconductor etching processes.

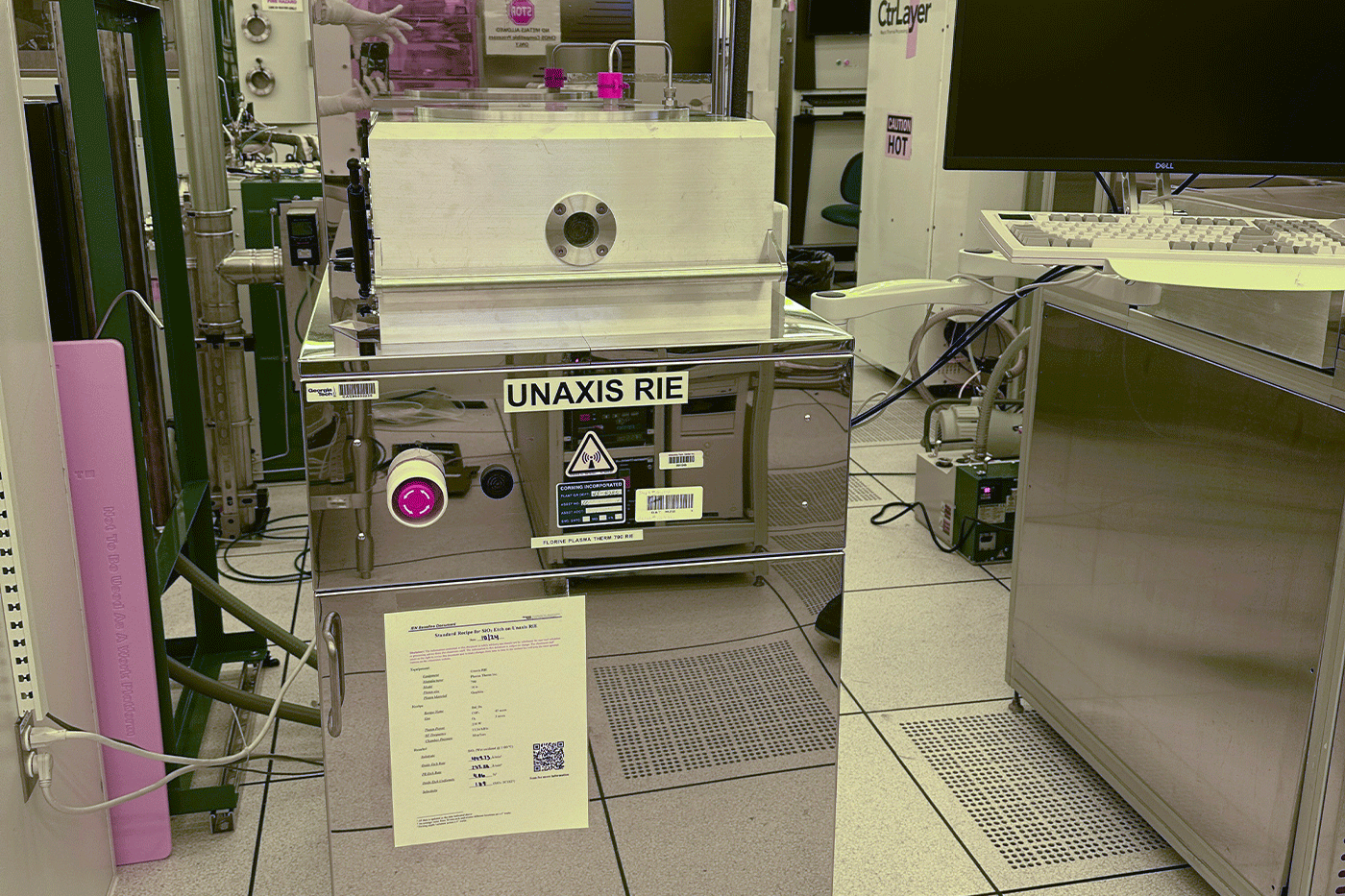

Unaxis RIE

The Georgia Tech Unaxis RIE 790-10-RIE system operates at 13.56 MHz and is used for etching materials like SiO2, SiNx. It supports small pieces and wafers up to 8 inches in size. The system utilizes reactive ion etching (RIE) with reactive gases in an RF plasma to etch various materials. The system features a 500W 13.56 MHz AE RF5S platen and operates within a process pressure range of 10-800 mTorr, with gases such as CF4, CHF3, Ar, and O2.

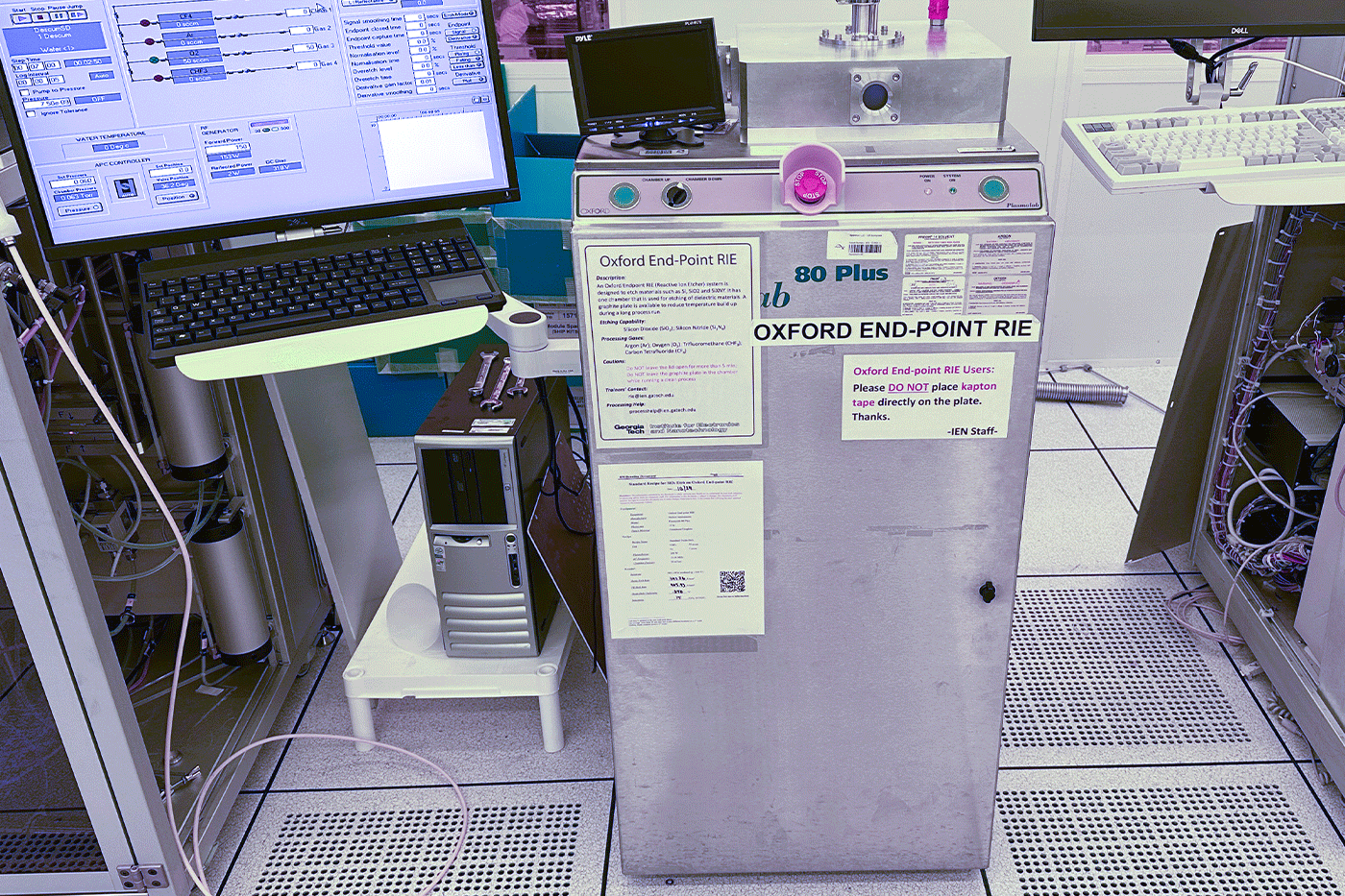

Oxford Endpoint RIE

The Georgia Tech Oxford Endpoint RIE system is specialized for etching dielectric materials such as SiO2 and SiXNY, operating at 13.56 MHz. This system is dedicated to plasma etching and is not suited for metal etching. It is equipped with a graphite plate that helps manage temperature buildup during extended etching runs. The system accommodates small pieces and wafers up to 8 inches in size. It uses gases like Ar, O2, CHF3, and CF4, with a process pressure range of 5-500 mTorr. The system features a 500W 13.56 MHz AE platen and can operate at power settings up to 300W, providing efficient etching for dielectric materials. Metal masks are compatible with the system for specific etching applications.

Plasma Therm RIE

The Georgia Tech Plasma-Therm 700 RIE system is a dual-chamber Reactive Ion Etching (RIE) system operating at 13.56 MHz, designed for etching a variety of materials, including dielectrics and metals like Al, Cr, Ti, and III-V semiconductors. The system accommodates small pieces and substrates up to 10 inches. The left chamber is ideal for etching metals, III-V materials, and silicon, while the right chamber is configured for etching dielectrics such as SiO2, Si3N4, polyimide, SU8, and BCB. Both chambers support metal and photoresist masks. With a process pressure range of 10-800 mTorr, it utilizes gases like Ar, CHF3, O2, and SF6 for precise etching. Each chamber features a 500W 13.56 MHz RFPP RF-5S power supply for efficient processing. The system is capable of handling small pieces, including one 8-inch wafer in the left chamber and up to four 100mm wafers in the right chamber, offering versatility for various semiconductor fabrication processes.

Additional Tools

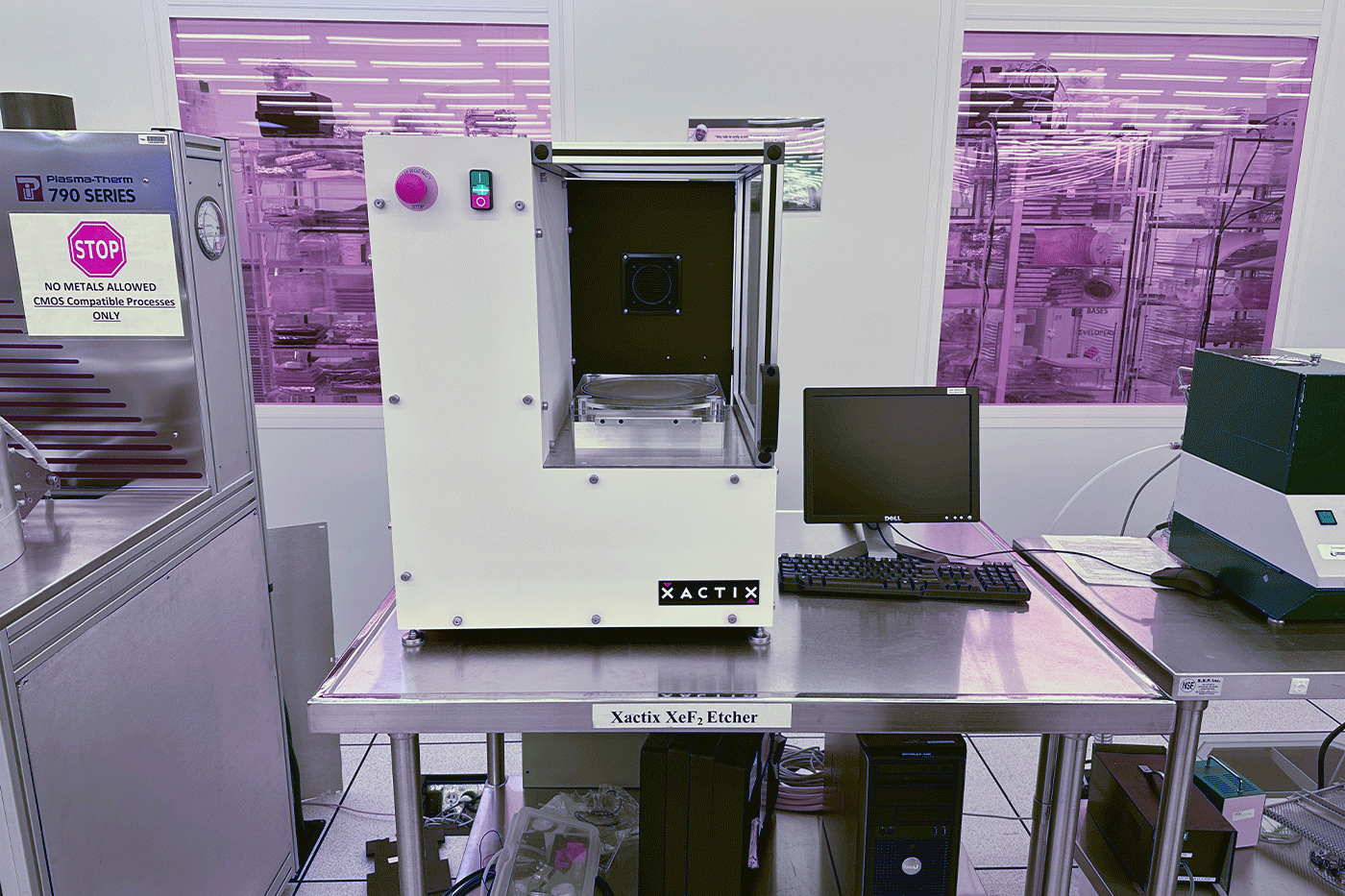

Xactix Xenon Difluoride Etcher

The Georgia Tech Xactix Xenon Difluoride e1 MOD Etcher utilizes xenon difluoride (XeF2) gas to isotropically dry etch silicon (Si), poly-silicon, germanium, and molybdenum, making it a versatile tool for etching applications. The gas is introduced through a showerhead to provide uniform etching, and the system is capable of processing pieces up to 4-inch wafers. Known for its excellent selectivity, the system offers a selectivity ratio of 1000:1 for SiO2 to Si, ensuring minimal etching of the underlying silicon. It is especially valuable for processing very small devices, with etching capabilities as small as 30nm. The etching process does not attack the Bosch passivation layer, allowing users to seamlessly switch between tools while still protecting the trench walls. The system supports etching with masks such as photoresist (PR), SiO2, and Si3N4. Xenon difluoride (XeF2) provides a unique chemical etching capability that makes it an effective tool for applications in semiconductor device fabrication, especially for precise etching of critical features.

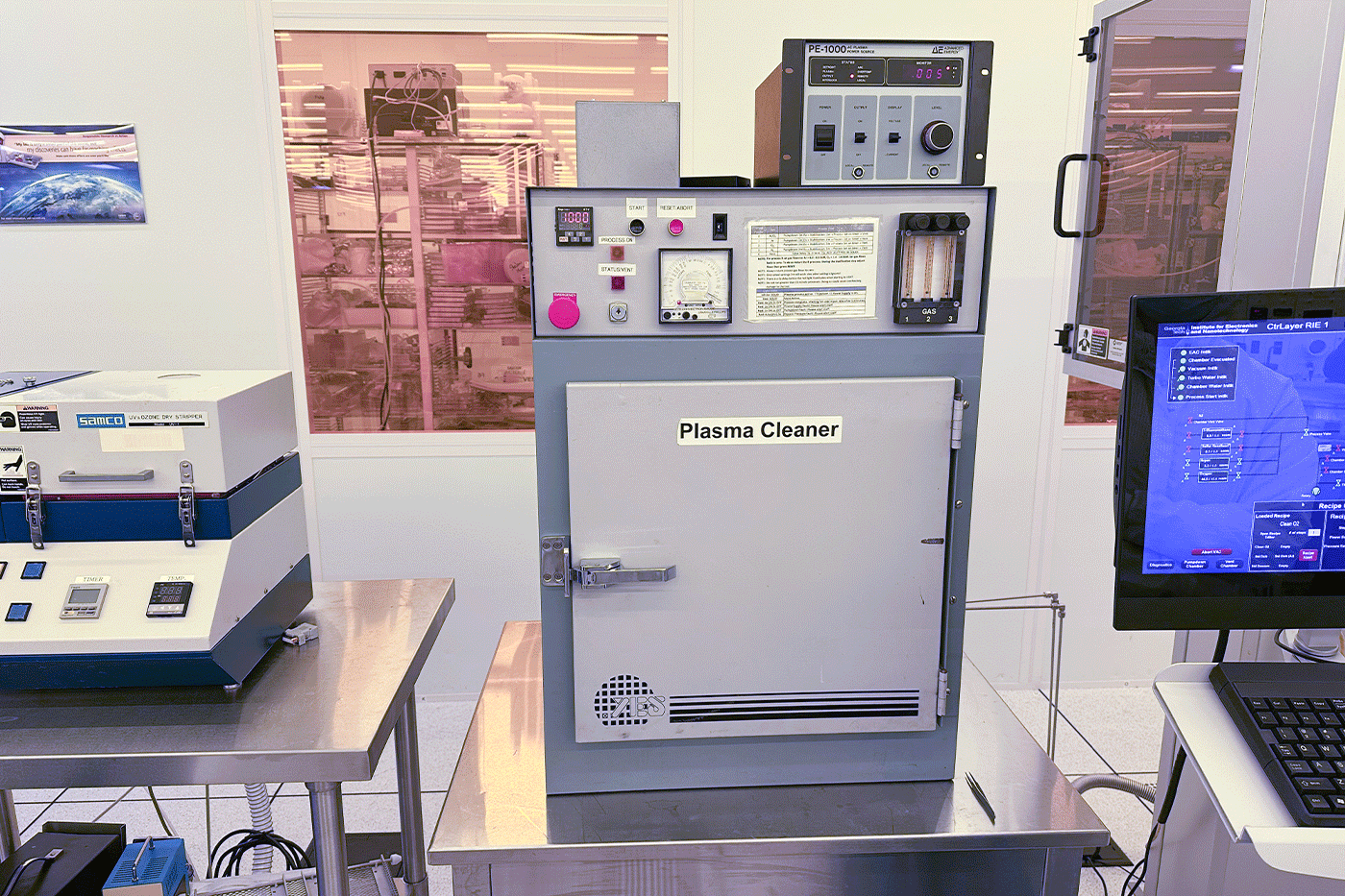

YES-R1 Plasma Cleaner

The Georgia Tech YES-R1 Plasma Cleaner uses ionized gas (plasma) in a low-pressure environment to effectively descum and remove residual organics and thin oxides from samples. Operating at process pressures of 1500 mTorr, the system utilizes gases such as O2, Ar, and N2 for cleaning. It supports a wide range of substrate sizes, from small pieces to larger samples up to 12" x 12" x 4". The chamber temperature typically ranges from 25°C to 80°C, with heat generated from the plasma. The system is controlled through a MicroLogix PLC upgrade, ensuring precise and efficient processing for various cleaning applications.

Samco UV Ozone Dry Stripper

The UV-1 is a compact and versatile benchtop UV ozone cleaning system designed for safe, efficient, and precise organic contaminant removal from a wide range of substrates. Combining ultraviolet irradiation, ozone generation, and a heated stage, the UV-1 delivers high-performance cleaning while preserving substrate integrity. Ideal for semiconductor, optics, and advanced materials applications, it supports up to 100 mm substrates including silicon, glass, ceramics, and compound semiconductors. With user-friendly, vacuum-free operation, robust safety features, and a small lab footprint, the UV-1 is an excellent solution for precision surface preparation and modification.